DRV8302 - DRV8302 - 高性能BLDC驱动器

使用Arduino UNO

DRV8302是一款高性能BLDC驱动板,能够持续提供15A电流,峰值电流可达27A。它具备温度和过流保护功能,支持反电动势和三相电流检测,最重要的是,它仅需3PWM信号即可运行,这使其与简易FOC库兼容。

注意📢

截至目前(1.4.1版本 ),该库尚未实现电流控制环。电机扭矩直接通过电压控制。 更多信息。

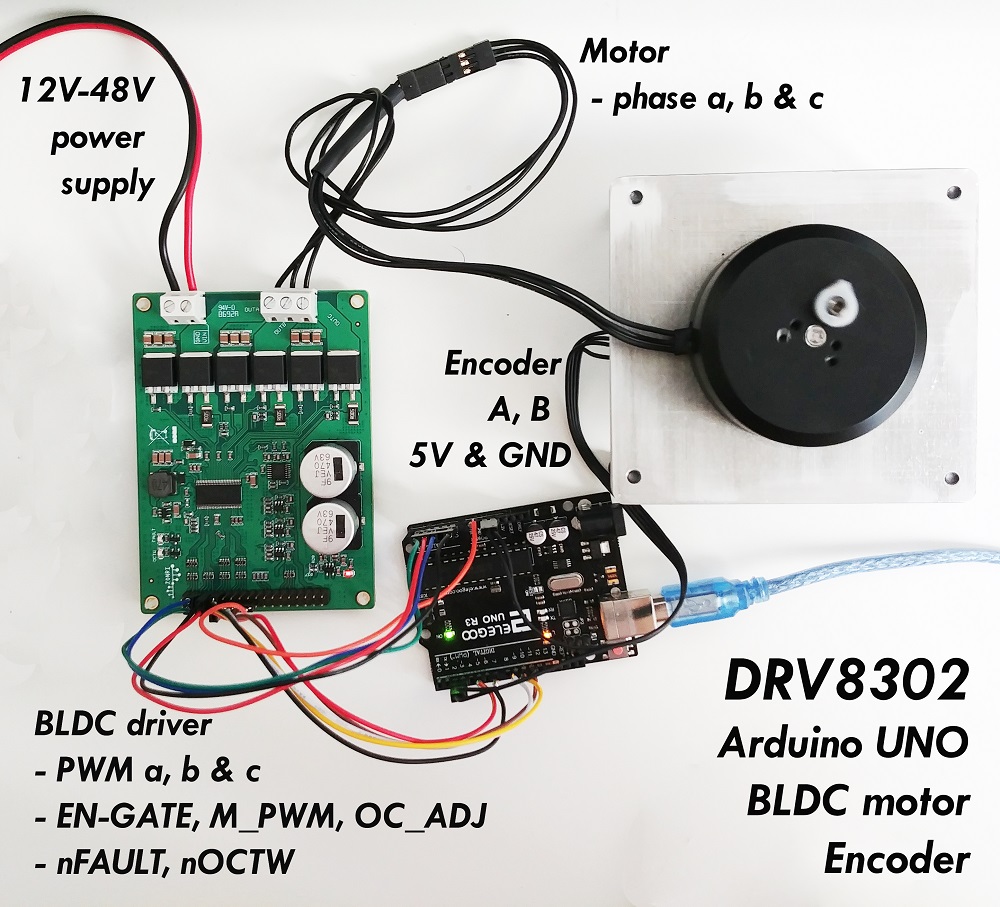

以下是此项目可能需要的硬件示例:

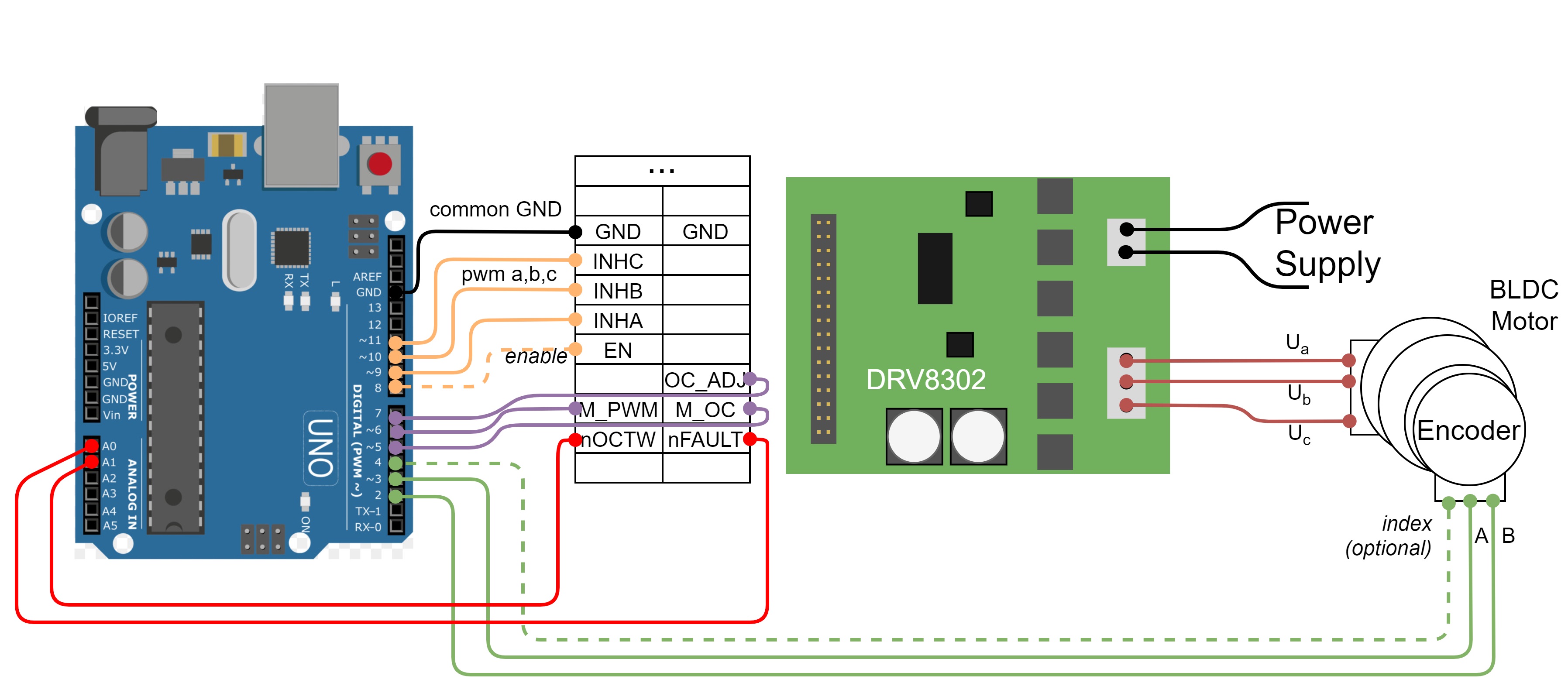

以下是使用Arduino UNO的连接方案示例:

DRV8302

- 与本库支持的其他BLDC驱动器一样,该板接收3PWM信号:pwm

a、b和c。将它们连接到INHA、INHB和INHC - 此外,还需将使能引脚连接到

EN-GATE引脚 - 要配置BLDC驱动器,我们需要三个引脚(紫色)

M_PWM为高电平时启用3PWM模式(为低电平时,板载期望6PWM信号)M_OC为低电平时启用过流保护OC_ADJ模拟输入,用于调节过流限制 - 若不关心,可接高电平

- 要读取故障信号,我们需要读取两个引脚(红色)

nFAULT为高电平时,板载处于故障状态nOCTW为高电平时,达到过流限制

编码器

- 通道

A和B连接到外部中断引脚2和3 - 若编码器有

index信号,可连接到任何可用的数字引脚,此处我们将其连接到引脚4

电机

- 电机相

a、b和c直接连接到板载端子OUTA、OUTB和OUTC

示例连接

Arduino代码3PWM

使用3PWM运行DRV8302板的代码与其他低功率BLDC驱动器的代码几乎完全相同。唯一的区别是DRV8302的配置过程。

因此,让我们首先开始定义我们在板上使用的引脚:

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 9

#define INH_B 10

#define INH_C 11

#define EN_GATE 8

#define M_PWM 6

#define M_OC 5

#define OC_ADJ 7

变量INH_A、INH_B、INH_C和EN_GATE直接提供给BLDCDriver3PWM类构造函数。

// driver instance

BLDCDriver3PWM driver = BLDCDriver3PWM(INH_A, INH_B, INH_C, EN_GATE);

代码中另一个特定于DRV8302的部分是,需要在setup()函数的开头添加相关配置。

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,LOW);

// M_PWM - enable 3pwm mode

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,HIGH);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

其余部分是运行BLDC电机的常规简易FOC库代码。

以下是该项目的完整代码:

#include <SimpleFOC.h>

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 9

#define INH_B 10

#define INH_C 11

#define EN_GATE 8

#define M_PWM 6

#define M_OC 5

#define OC_ADJ 7

// motor instance

BLDCMotor motor = BLDCMotor(11);

// driver instance

BLDCDriver3PWM driver = BLDCDriver3PWM(INH_A, INH_B, INH_C, EN_GATE);

// encoder instance

Encoder encoder = Encoder(2, 3, 8192);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

// commander interface

Commander command = Commander(Serial);

void onMotor(char* cmd){ command.motor(&motor, cmd); }

void setup() {

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,LOW);

// M_PWM - enable 3pwm mode

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,HIGH);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

// configure driver

driver.voltage_power_supply = 12;

driver.init();

motor.linkDriver(&driver);

// choose FOC modulation

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set control loop type to be used

motor.controller = MotionControlType::torque;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// angle loop velocity limit

motor.velocity_limit = 50;

// default voltage_power_supply

motor.voltage_limit = 12;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// set the initial target value

motor.target = 2;

// define the motor id

command.add('M', onMotor, "motor");

_delay(1000);

}

void loop() {

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outer loop target

// velocity, position or voltage

// if target not set in parameter uses motor.target variable

motor.move();

// user communication

command.run();

}

Arduino代码6PWM

使用6PWM运行DRV8302板的代码,我们需要根据所使用的微控制器正确配置引脚。

Arduino uno引脚分配示例如下。

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 5

#define INH_B 9

#define INH_C 11

#define INL_A 6

#define INL_B 10

#define INL_C 3

#define EN_GATE 8

#define M_PWM 6

#define M_OC 5

#define OC_ADJ 7

对于stm32 Nucleo板,上述引脚分配不适用,但有相应适用的引脚分配。

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 7

#define INH_B 6

#define INH_C 5

#define INL_A 2

#define INL_B 3

#define INL_C 4

#define EN_GATE 8

#define M_PWM 9

#define M_OC 10

#define OC_ADJ 11

变量INH_A、INH_B、INH_C、INL_A、INL_B、INHL_C和EN_GATE直接提供给BLDCDriver6PWM类构造函数。

// driver instance

BLDCDriver6PWM driver = BLDCDriver6PWM(INH_A, INL_A, INH_B,INL_B, INH_C, INL_C, EN_GATE);

代码中另一个特定于DRV8302的部分是,需要在setup()函数的开头添加相关配置。

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,LOW);

// M_PWM - enable 6pwm mode (can be left open)

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,LOW);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

其余部分是运行BLDC电机的常规简易FOC库代码。

以下是该项目的完整代码:

#include <SimpleFOC.h>

// DRV8302 pins connections

// don't forget to connect the common ground pin

#define INH_A 5

#define INH_B 9

#define INH_C 11

#define INL_A 6

#define INL_B 10

#define INL_C 3

#define EN_GATE 8

#define M_PWM 6

#define M_OC 5

#define OC_ADJ 7

// motor instance

BLDCMotor motor = BLDCMotor(11);

// driver instance

BLDCDriver6PWM driver = BLDCDriver6PWM(INH_A, INL_A, INH_B,INL_B, INH_C, INL_C, EN_GATE);

// encoder instance

Encoder encoder = Encoder(2, 3, 8192);

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

// commander interface

Commander command = Commander(Serial);

void onMotor(char* cmd){ command.motor(&motor, cmd); }

void setup() {

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB);

// link the motor to the sensor

motor.linkSensor(&encoder);

// DRV8302 specific code

// M_OC - enable over-current protection

pinMode(M_OC,OUTPUT);

digitalWrite(M_OC,LOW);

// M_PWM - enable 6pwm mode (can be left open)

pinMode(M_PWM,OUTPUT);

digitalWrite(M_PWM,LOW);

// OD_ADJ - set the maximum over-current limit possible

// Better option would be to use voltage divisor to set exact value

pinMode(OC_ADJ,OUTPUT);

digitalWrite(OC_ADJ,HIGH);

// configure driver

driver.voltage_power_supply = 12;

driver.init();

motor.linkDriver(&driver);

// choose FOC modulation

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// set control loop type to be used

motor.controller = MotionControlType::torque;

// controller configuration based on the control type

motor.PID_velocity.P = 0.2;

motor.PID_velocity.I = 20;

// velocity low pass filtering time constant

motor.LPF_velocity.Tf = 0.01;

// angle loop controller

motor.P_angle.P = 20;

// angle loop velocity limit

motor.velocity_limit = 50;

// default voltage_power_supply

motor.voltage_limit = 12;

// use monitoring with serial for motor init

// monitoring port

Serial.begin(115200);

// comment out if not needed

motor.useMonitoring(Serial);

// initialize motor

motor.init();

// align encoder and start FOC

motor.initFOC();

// set the initial target value

motor.target = 2;

// define the motor id

command.add('M', onMotor, "motor");

_delay(1000);

}

void loop() {

// iterative setting FOC phase voltage

motor.loopFOC();

// iterative function setting the outer loop target

// velocity, position or voltage

// if target not set in parameter uses motor.target variable

motor.move();

// user communication

command.run();

}