PID控制器原理 v2.1

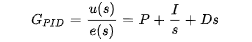

本库实现的PID控制器的传递函数为:

连续PID被转换到离散域,可以描述为三个部分的总和:

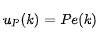

比例部分:

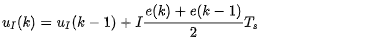

积分部分:

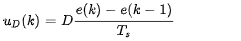

微分部分:

其中,u(k)是时刻k的控制信号(在我们的例子中是电压Uq),e(k)、e(k-1)是当前时刻k和前一步k-1的跟踪误差。跟踪误差是目标速度值vd和测量速度v之间的差值。

实现细节

PID算法在SimpleFOC库中通过PIDController类实现。实例化该类时需要指定参数。

PIDController(float P, float I, float D, float ramp, float limit);

该类只有一个函数:

// PID controller function

float PIDController::operator() (float error){

// calculate the time from the last call

unsigned long timestamp_now = _micros();

float Ts = (timestamp_now - timestamp_prev) * 1e-6;

// quick fix for strange cases (micros overflow)

if(Ts <= 0 || Ts > 0.5) Ts = 1e-3;

// u(s) = (P + I/s + Ds)e(s)

// Discrete implementations

// proportional part

// u_p = P *e(k)

float proportional = P * error;

// Tustin transform of the integral part

// u_ik = u_ik_1 + I*Ts/2*(ek + ek_1)

float integral = integral_prev + I*Ts*0.5*(error + error_prev);

// antiwindup - limit the output voltage_q

integral = _constrain(integral, -limit, limit);

// Discrete derivation

// u_dk = D(ek - ek_1)/Ts

float derivative = D*(error - error_prev)/Ts;

// sum all the components

float output = proportional + integral + derivative;

// antiwindup - limit the output variable

output = _constrain(output, -limit, limit);

// limit the acceleration by ramping the output

float output_rate = (output - output_prev)/Ts;

if (output_rate > output_ramp)

output = output_prev + output_ramp*Ts;

else if (output_rate < -output_ramp)

output = output_prev - output_ramp*Ts;

// saving for the next pass

integral_prev = integral;

output_prev = output;

error_prev = error;

timestamp_prev = timestamp_now;

return output;

}

因此,你可以很容易地将PID集成到你的代码中。

void setup(){

...

PIDController some_pid = PIDController{.....};

...

}

void loop(){

float control = some_pid(target-measurement);

}

这个PID类在BLDCMotor和StepperMotor类中实现,用于处理运动控制的速度(motor.PID_velocity)和位置(motor.P_angle)。你可以通过修改这些PID控制器的公共变量来改变它们的参数:

// PID controller configuration structure

class PIDController

{

.....

float P; //!< Proportional gain

float I; //!< Integral gain

float D; //!< Derivative gain

....

};

例如:

motor.PID_velocity.P = 1;

motor.P_angle.P = 10;