On this page

Position open-loop control

This control loop allows you to move your motor to the desired angle in real time without using the position sensor. This mode is enabled by:

// set position motion control open-loop

motor.controller = MotionControlType::angle_openloop;

Choose the motor type:

Choose the voltage control type:

Voltage limiting Current limiting Current limiting with Back-EMF compensation

.png)

You can test this algorithm by running the examples in the motion_control/open_loop_motor_control/ folder.

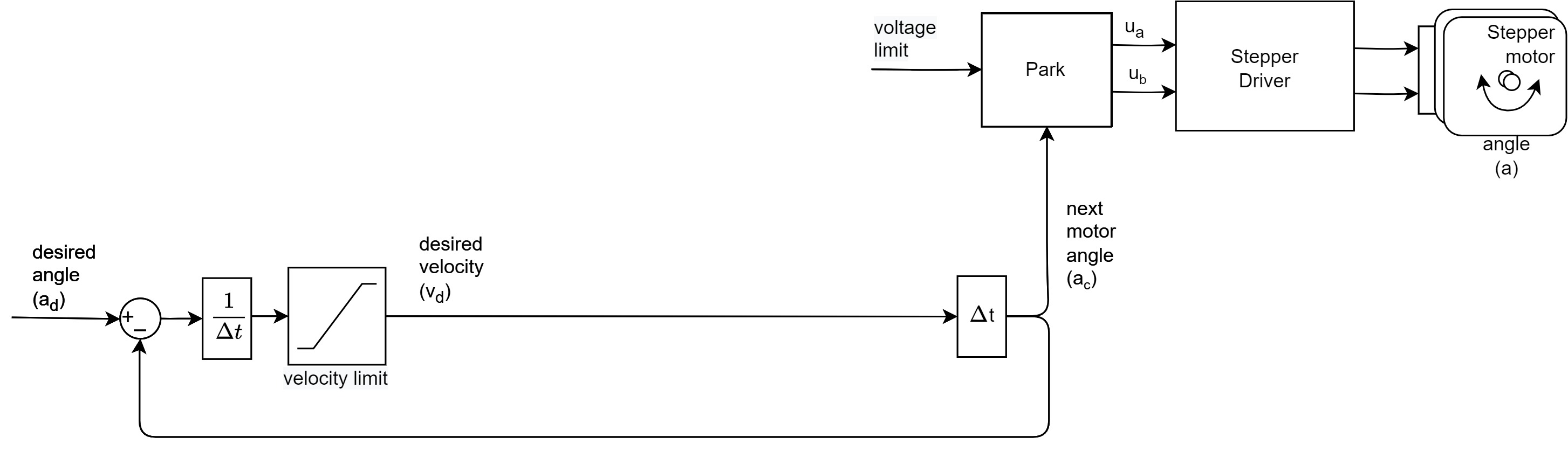

This control algorithm is very simple. User sets the target angle it wants to achieve \(a_d\). The algorithm only subtracts the current angle \(a_c\) and the desired angle \(a_d\) to find the direction it needs to move and goes in that direction with the highest velocity possible motor.velocity_limit(max velocity \(v_{max}\)). To set this velocity it uses the same algorithm as for velocity open-loop control. It integrates the velocity it in time to find out what is the angle it needs to set to the motor \(a_c\) in order to achieve it. Then the maximal allowed voltage motor.voltage_limit (\(U_{limit}\)) is going to be applied in the direction of the \(a_c\) using SinePWM or SpaceVector modulation.

In each step of the control loop, the algorithm calculates the distance from the target angle \(a_d\) and the current angle \(a_c\). It then calculates the next angle \(a_{c}\) using the following formula:

\[a_c = a_c + \begin{cases} v_{nax}\Delta t, & \text{if } a_d - a_c > v_{max}\Delta t \\ -v_{max}\Delta t, & \text{if } a_d - a_c < -v_{max}\Delta t \\ a_d - a_c, & \text{otherwise} \end{cases}\]A more compact way to write this is:

\[a_c = a_c + \max(-v_{max}\Delta t,~ \min(v_{max}\Delta t,~ a_d - a))\]Or in code

// calculate the distance from the target

d_angle = target_angle - past_angle;

// constrain the distance with maximal allowable displacement

d_angle = constrain(d_angle, -velocity_limit*d_time, velocity_limit*d_time)

// calculate the next angle

next_angle = past_angle + d_angle;

Configuration

// choose FOC modulation (optional)

motor.foc_modulation = FOCModulationType::SpaceVectorPWM;

// maximal velocity of the position control

// default 20

motor.velocity_limit = 20;

// limiting voltage

motor.voltage_limit = 3; // Volts

// or current - if phase resistance provided

motor.current_limit = 0.5 // Amps

The angle open-loop control will (if not provided phase resistance) set the voltage to the motor equal to the motor.voltage_limit (\(U_{limit}\))

This is very inefficient, as for different motors with different phase resistances the same voltage values can produce wildly different currents. For gimbal motor, you can run it in the open loop with the voltage limits of 5-10 Volts and it will reach the currents of 0.5-2 amps as it has the phase resistance from 5-15 Ohms. For drone motors, the voltage limits should stay very low, under 1 volt. Because they have phase resisatnce of 0.05 to 0.2 Ohms.

Current limiting approaches

We suggest you to provide the motor class with the phase_resistance (\(R\)) value and set the motor.current_limit (\(I_{limit}\)) instead the voltage limit. This current might be surpassed but at least you will know an approximate current your motor is drawing. You can calculate the current the motor is going to be producing by checking the motor resistance phase_resistance and evaluating:

The best way to use this control strategy would be to provide both phase resistance value and KV rating of your motor. The the library would be able to calculate he back-EMF voltage and much more precisely estimate the consumed current. And with the current and the back-EMF current the library can set much more appropriate voltage to the motor.

\[U_{limit} = I_{limit}\cdot R + \frac{v_{max}}{KV} \quad [ Amps ]\]Velocity limit

The maximal velocity motor.velocity_limit (\(v_{max}\)) value is going to determine how fast your motor goes in between positions. The higher the value the faster the transition. But since we are turning the motor in open-loop we will not be able to know if the motor can follow the velocity. So make sure to put the velocity_limit value that is achievable for your motor. Also beware that for higher velocities and more holding torque you will need to increase the motor.voltage_limit (\(v_{max}\)) or motor.current_limit (\(I_{limit}\)) variable as well.

Changing limits in real-time

Also, you can change the voltage limit motor.voltage_limit (motor.current_limit) and transition velocity motor.velocity_limit in real-time if you need this kind of behavior in your application.

Position open-loop control example

Here is one basic example of the velocity open-loop control with the complete configuration. The program will set the target position of 0 RAD and maintain it, and the user can change the target position using serial terminal.

// Open loop motor control example

#include <SimpleFOC.h>

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(11);

BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&motor.target, cmd); }

void doLimitVolt(char* cmd) { command.scalar(&motor.voltage_limit, cmd); }

void doLimitVelocity(char* cmd) { command.scalar(&motor.velocity_limit, cmd); }

void setup() {

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

motor.voltage_limit = 3; // [V]

motor.velocity_limit = 5; // [rad/s] cca 50rpm

// open loop control config

motor.controller = MotionControlType::angle_openloop;

// init motor hardware

motor.init();

motor.initFOC();

// add target command T

command.add('T', doTarget, "target angle");

command.add('L', doLimitVolt, "voltage limit");

command.add('V', doLimitVelocity, "velocity limit");

Serial.begin(115200);

Serial.println("Motor ready!");

Serial.println("Set target position [rad]");

_delay(1000);

}

void loop() {

motor.loopFOC();

// open loop angle movements

// using motor.voltage_limit and motor.velocity_limit

motor.move();

// user communication

command.run();

}

.png)

.png)

.jpg)

.jpg)