On this page

Motion control implementation v1.6

SimpleFOClibrary implements 3 motion control loops:

- Torque control using voltage

- Velocity motion control

- Position/angle control

The motion control algorithm is chosen by seting the motor.controller variables with one of the ControlType structure:

// Motion control type

enum ControlType{

voltage,// Torque control using voltage

velocity,// Velocity motion control

angle// Position/angle motion control

};

This will look like:

motor.controller = ControlType::voltage;

// or

motor.controller = ControlType::velocity;

// or

motor.controller = ControlType::angle;

This variable can be changed in real-time as well!

Real-time execution move()

The real-time motion control is executed inside move() function. Move function receives executes one of the control loops based on the controller variable. The parameter new_target of the move() function is the target value so be set to the control loop. The new_target value is optional and doesn’t need to be set. If it is not set the motion control will use motor.target variable.

Here is the implementation:

// Iterative function running outer loop of the FOC algorithm

// Behavior of this function is determined by the motor.controller variable

// It runs either angle, velocity or voltage loop

// - needs to be called iteratively it is asynchronous function

// - if target is not set it uses motor.target value

void BLDCMotor::move(float new_target = NOT_SET) {

// check if target received through the parameter new_target

// if not use the internal target variable (motor.target)

if( new_target != NOT_SET ) target = new_target;

// get angular velocity

shaft_velocity = shaftVelocity();

// choose control loop

switch (controller) {

case ControlType::voltage:

// set the target voltage for FCO loop

voltage_q = target;

break;

case ControlType::angle:

// angle set point

shaft_angle_sp = target;

// calculate the necessary velocity to achieve target position

shaft_velocity_sp = positionP( shaft_angle_sp - shaft_angle );

// calculate necessary voltage to be set by FOC loop

voltage_q = velocityPI(shaft_velocity_sp - shaft_velocity);

break;

case ControlType::velocity:

// velocity set point

shaft_velocity_sp = target;

// calculate necessary voltage to be set by FOC loop

voltage_q = velocityPI(shaft_velocity_sp - shaft_velocity);

break;

}

}

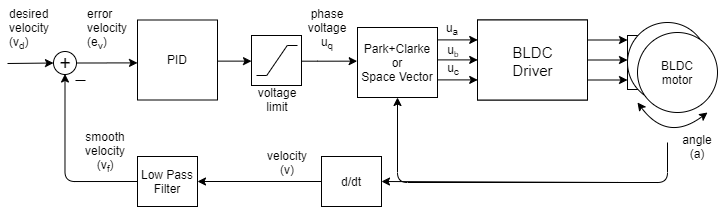

Shaft velocity filtering shaftVelocity

The first step for velocity motion control is the getting the velocity value from sensor. Because some sensors are very noisy and especially since in most cases velocity value is calculated by derivating the position value we have implemented a Low Pass filter velocity filter to smooth out the measurement. The velocity calculating function is shaftVelocity() with implementation:

// shaft velocity calculation

float BLDCMotor::shaftVelocity() {

float Ts = (_micros() - LPF_velocity.timestamp) * 1e-6;

// quick fix for strange cases (micros overflow)

if(Ts <= 0 || Ts > 0.5) Ts = 1e-3;

// calculate the filtering

float alpha = LPF_velocity.Tf/(LPF_velocity.Tf + Ts);

float vel = alpha*LPF_velocity.prev + (1-alpha)*sensor->getVelocity();

// save the variables

LPF_velocity.prev = vel;

LPF_velocity.timestamp = _micros();

return vel;

}

The low pass filter is standard first order low pass filter with one time constant Tf which is configured with motor.LPF_velocitystructure:

// Low pass filter structure

struct LPF_s{

float Tf; // Low pass filter time constant

long timestamp; // Last execution timestamp

float prev; // filtered value in previous execution step

};

Low-Pass velocity filter theory

For more info about the theory of the Low pass filter please visit theory lovers corner

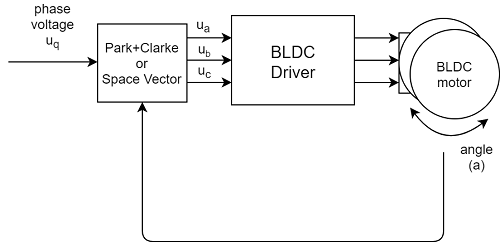

Torque control using voltage

Since for most of the low-cost gimbal motors and drivers current measurement is usually not available then the torque control has to be done using voltage directly.

This control loop makes an assumption that the voltage is proportional to the current which is proportional to the torque. Which is in general correct but not always. But in broad terms, it works pretty well for low current applications (gimbal motors). This is the same assumption we usually make with DC motors.

The control loop has trivial implementation, basically set the target voltage to the voltage_q variable in order to be set to the motor using the FOC algorithm loopFOC().

API usage

For more info about how to use this loop look into: voltage loop api docs

Torque control using voltage theory

For more info about the theory of the this type of control please visit theory lovers corner

Velocity motion control

Once we have the current velocity value and and the target value we would like to achieve, we need to calculate the appropriate voltage value to be set to the motor in order to follow the target value.

And that is done by using PI controller in velocityPI() function.

// velocity control loop PI controller

float BLDCMotor::velocityPI(float tracking_error) {

return controllerPI(tracking_error, PID_velocity);

}

The BLDCMotor class has implemented generic PI controller function called controllerPI().

// PI controller function

float BLDCMotor::controllerPI(float tracking_error, PI_s& cont){

float Ts = (_micros() - cont.timestamp) * 1e-6;

// quick fix for strange cases (micros overflow)

if(Ts <= 0 || Ts > 0.5) Ts = 1e-3;

// u(s) = (P + I/s)e(s)

// Tustin transform of the PI controller ( a bit optimized )

// uk = uk_1 + (I*Ts/2 + P)*ek + (I*Ts/2 - P)*ek_1

float tmp = cont.I*Ts*0.5;

float voltage = cont.voltage_prev + (tmp + cont.P) * tracking_error + (tmp - cont.P) * cont.tracking_error_prev;

// antiwindup - limit the output voltage_q

if (abs(voltage) > cont.voltage_limit) voltage = voltage > 0 ? cont.voltage_limit : -cont.voltage_limit;

// limit the acceleration by ramping the the voltage

float d_voltage = voltage - cont.voltage_prev;

if (abs(d_voltage)/Ts > cont.voltage_ramp) voltage = d_voltage > 0 ? cont.voltage_prev + cont.voltage_ramp*Ts : cont.voltage_prev - cont.voltage_ramp*Ts;

cont.voltage_prev = voltage;

cont.tracking_error_prev = tracking_error;

cont.timestamp = _micros();

return voltage;

}

The PI controller is configured with motor.PID_velocity structure:

// PI controller configuration structure

struct PI_s{

float P; // Proportional gain

float I; // Integral gain

float voltage_limit; // Voltage limit of the controller output

float voltage_ramp; // Maximum speed of change of the output value

long timestamp; // Last execution timestamp

float voltage_prev; // last controller output value

float tracking_error_prev; // last tracking error value

};

API usage

For more info about how to use this loop look into: velocity loop api docs

PI controller theory

For more info about the theory of hte PI controller implemented in this library please visit theory lovers corner

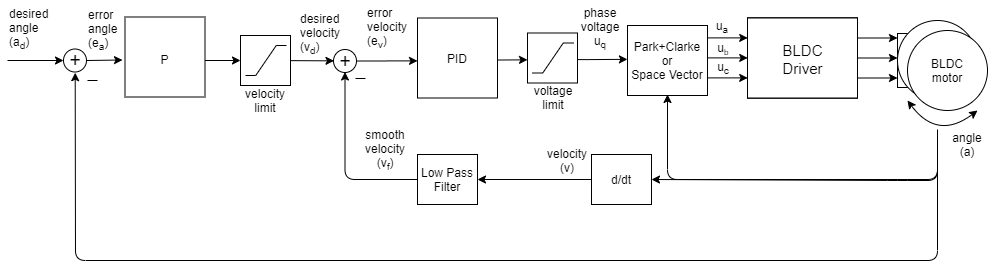

Position motion control

Now when we have the velocity control loop explained we can build our position control loop in cascade as shown on the image.

When we have target angle we want to achieve, we will use the P controller to calculate necessary velocity we need and then the velocity loop will calculate the necessary voltage votage_q to achieve both velocity and angle that we want.

The position P controller is implemented in positionP() function:

// P controller for position control loop

float BLDCMotor::positionP(float ek) {

// calculate the target velocity from the position error

float velocity_target = P_angle.P * ek;

// constrain velocity target value

if (abs(velocity_target) > velocity_limit) velocity_target = velocity_target > 0 ? velocity_limit : -velocity_limit;

return velocity_target;

}

And it is configured with motor.P_angle structure:

// P controller configuration structure

struct P_s{

float P; // Proportional gain

long timestamp; // Last execution timestamp

float velocity_limit; // Velocity limit of the controller output

};

API usage

For more info about how to use this loop look into: angle loop api docs