On this page

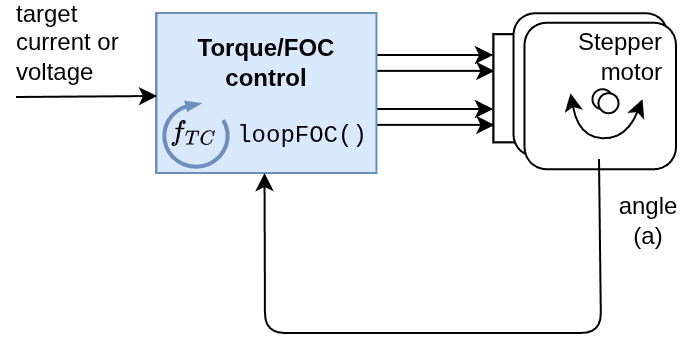

Torque control implementation v2.4+

BLDC motors Stepper motors Hybrid Stepper motors

The SimpleFOClibrary implements 4 different torque control strategies, selected via the motor.torque_controller parameter. All torque control modes are executed within the loopFOC() function and convert the current setpoint (current_sp) into voltage commands (voltage.q and voltage.d) that are applied to the motor.

Torque Control Modes

// Torque control type

enum TorqueControlType : uint8_t {

voltage = 0x00, // Torque control using voltage

dc_current = 0x01, // Torque control using DC current

foc_current = 0x02, // Torque control using dq currents

estimated_current = 0x03 // Torque control using estimated current

};

The torque control mode is selected by setting:

motor.torque_controller = TorqueControlType::voltage; // or dc_current, foc_current, estimated_current

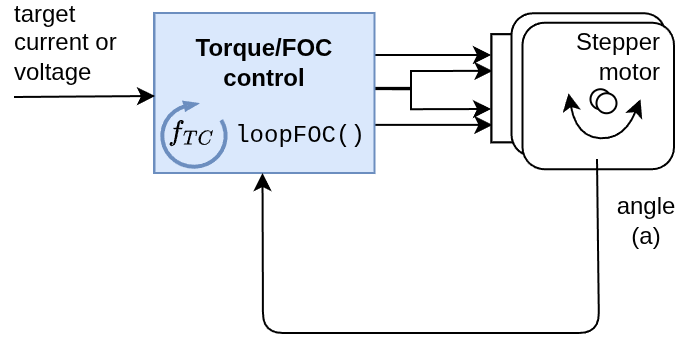

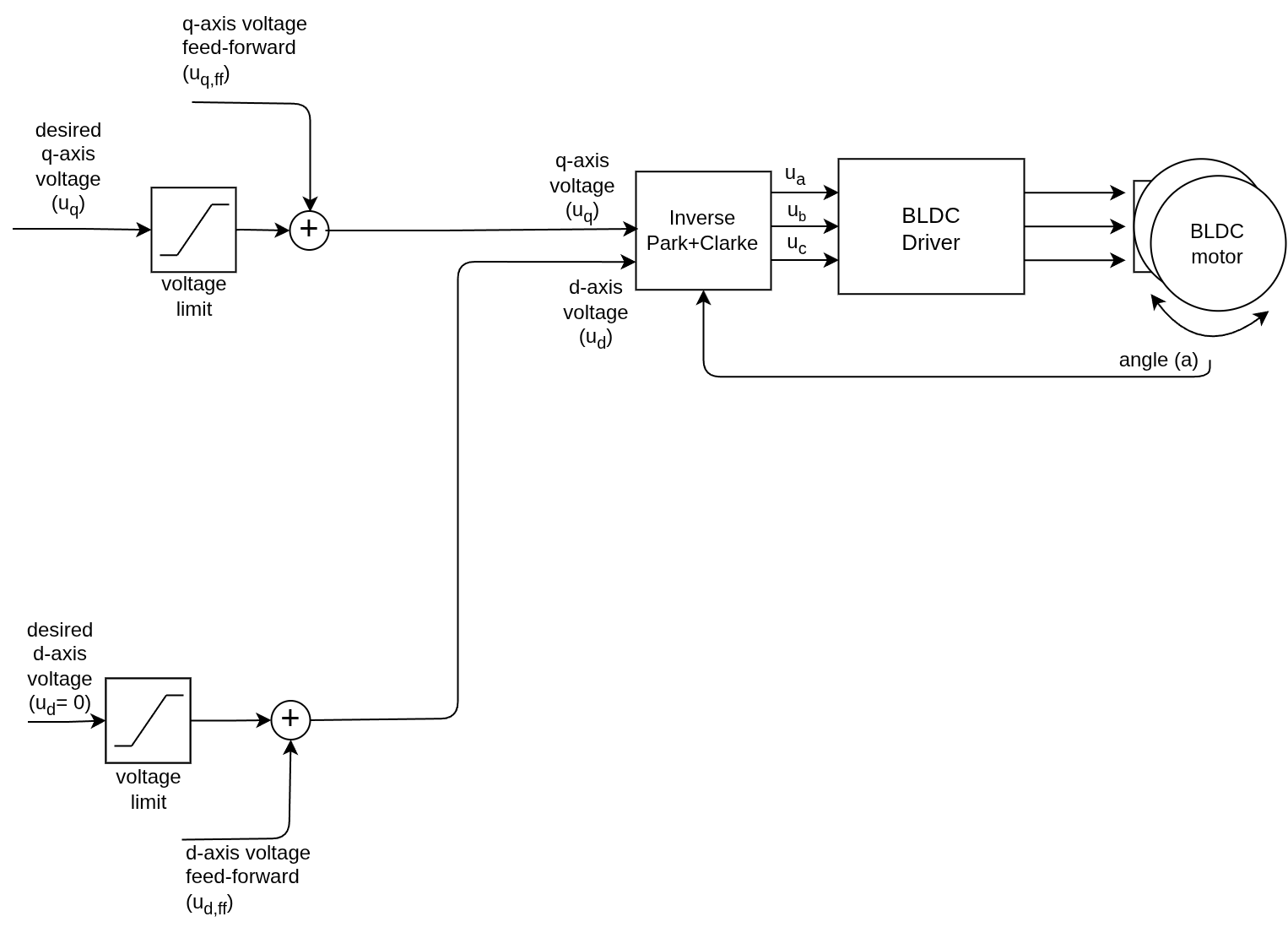

Voltage Mode

Type: TorqueControlType::voltage

The simplest torque control method, suitable when current sensing is not available. It assumes that voltage is proportional to current, which is proportional to torque.

BLDC motors Stepper motors Hybrid Stepper motors

Implementation

From FOCMotor::loopFOC():

case TorqueControlType::voltage:

voltage.q = _constrain(current_sp, -voltage_limit, voltage_limit) + feed_forward_voltage.q;

voltage.d = feed_forward_voltage.d;

break;

Configuration

motor.torque_controller = TorqueControlType::voltage;

motor.voltage_limit = 12.0; // Maximum voltage [V]

motor.feed_forward_voltage.q = 0.0; // Optional feed-forward

motor.feed_forward_voltage.d = 0.0;

See the voltage control API documentation See a deeper dive in voltage control theory

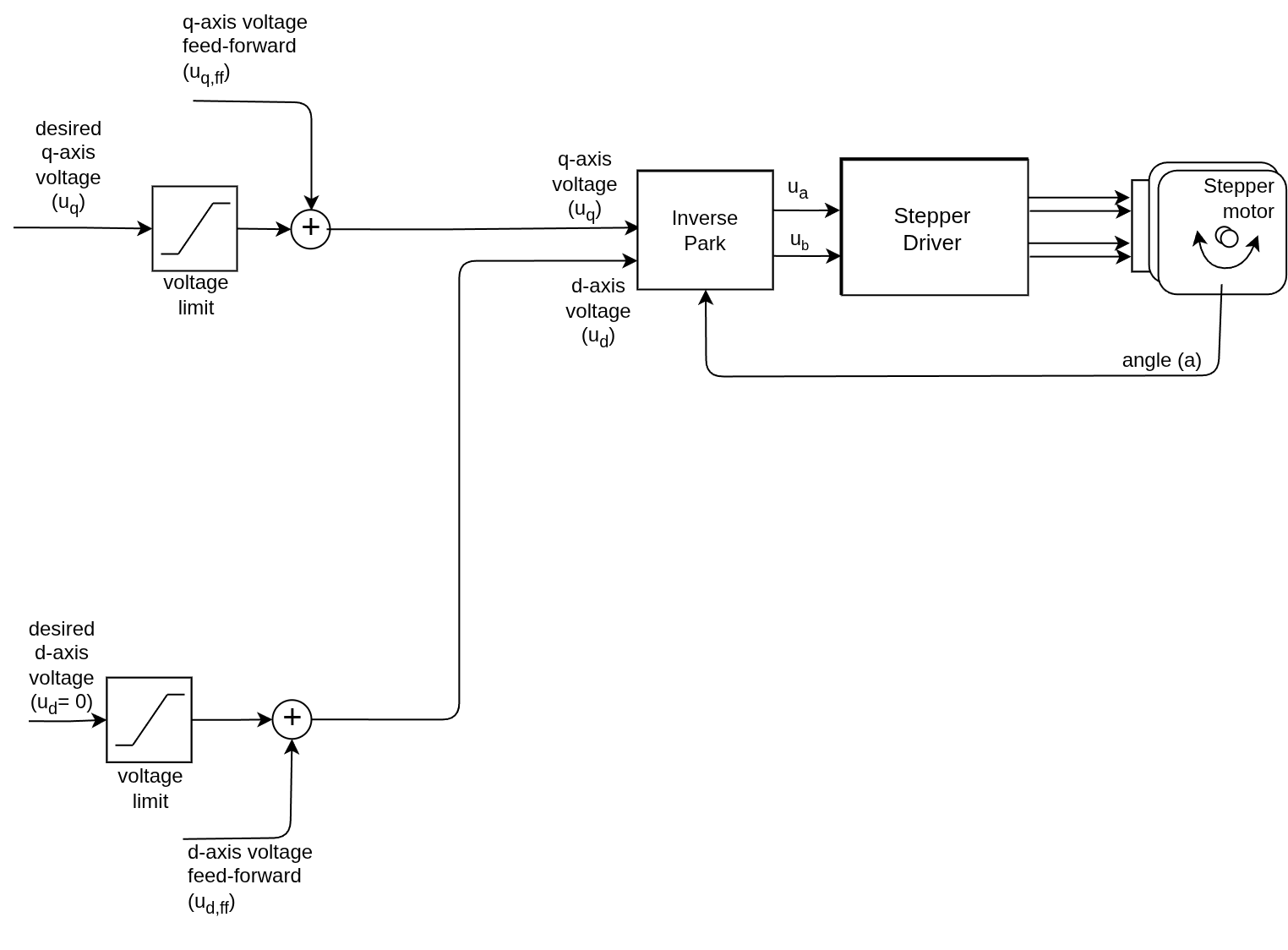

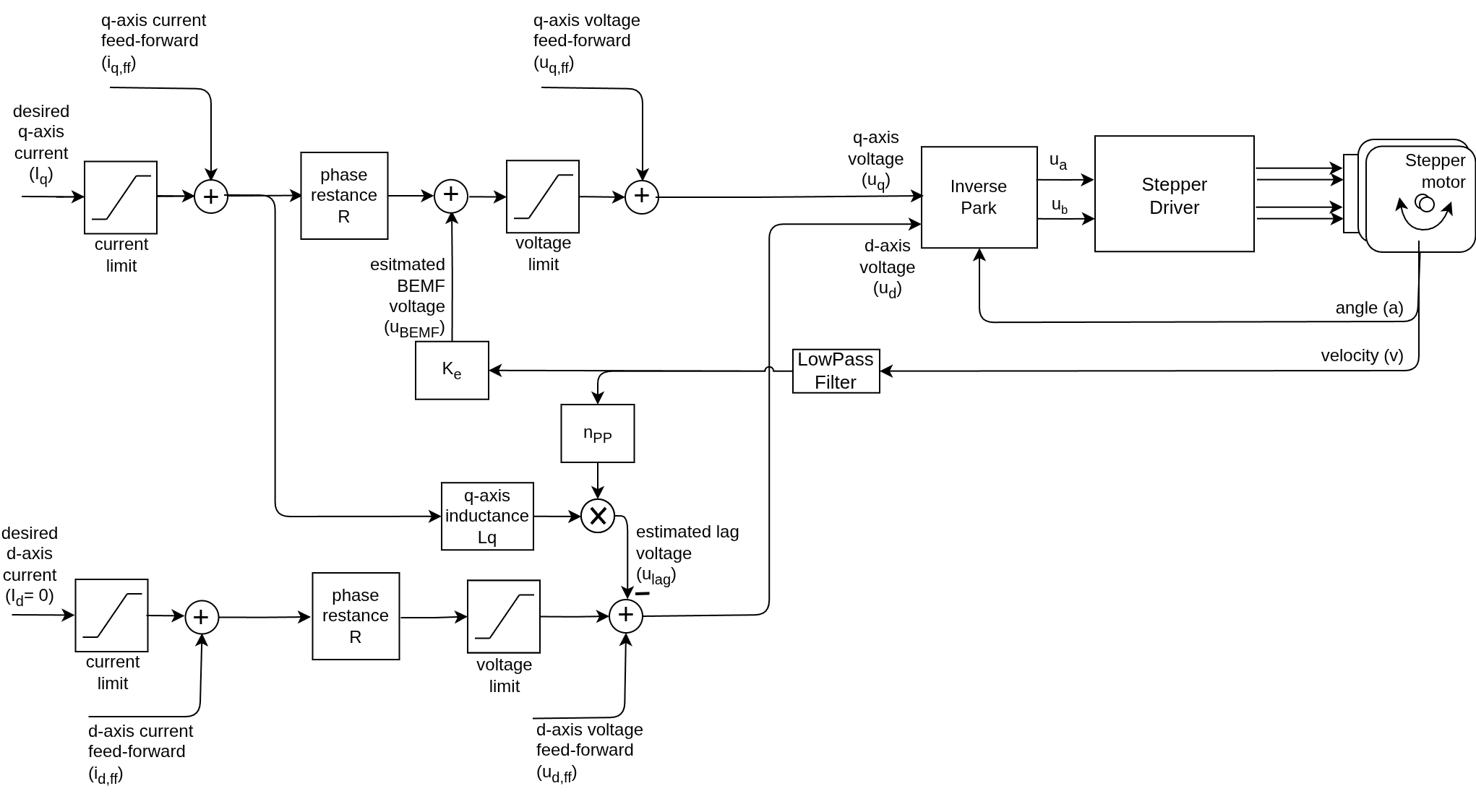

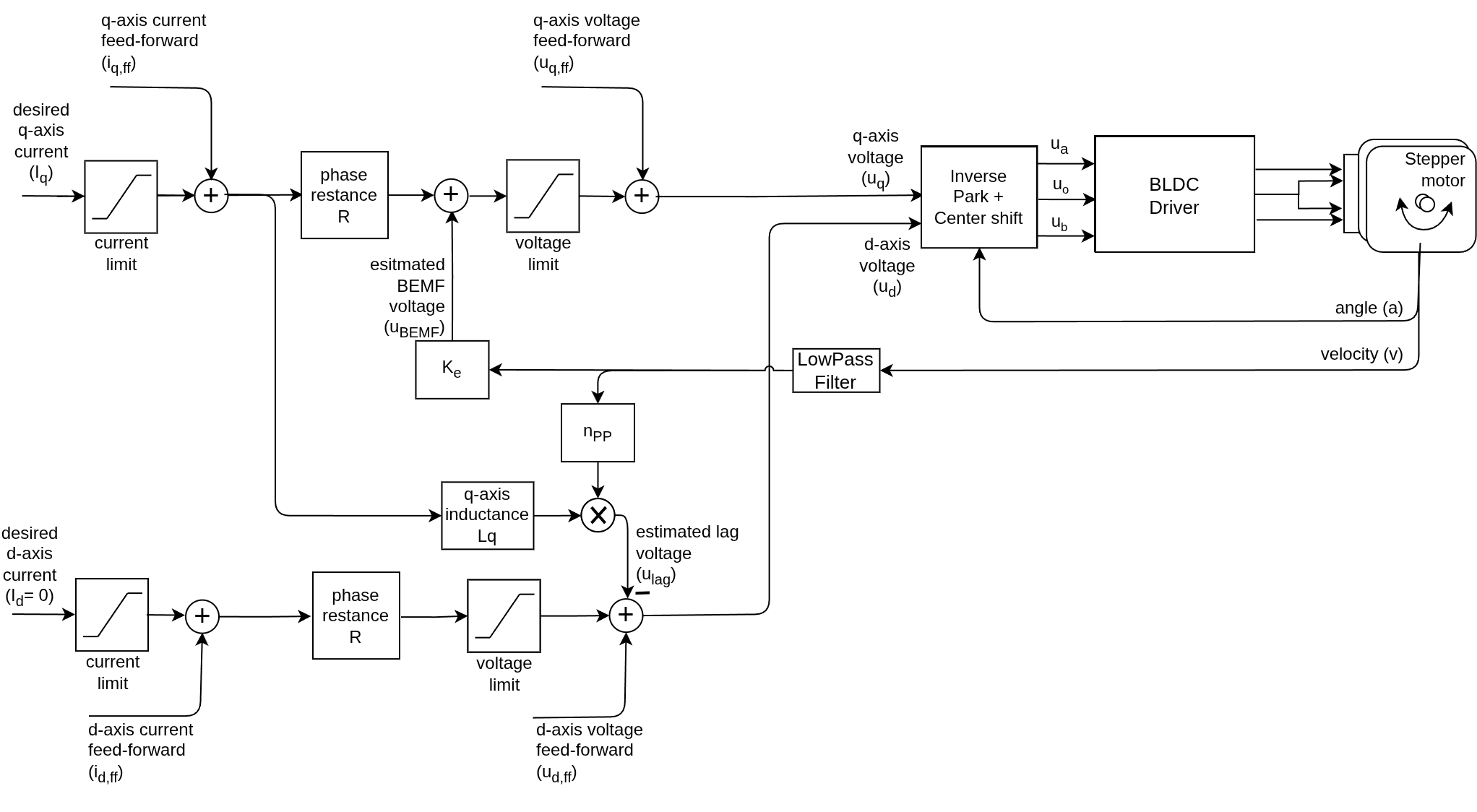

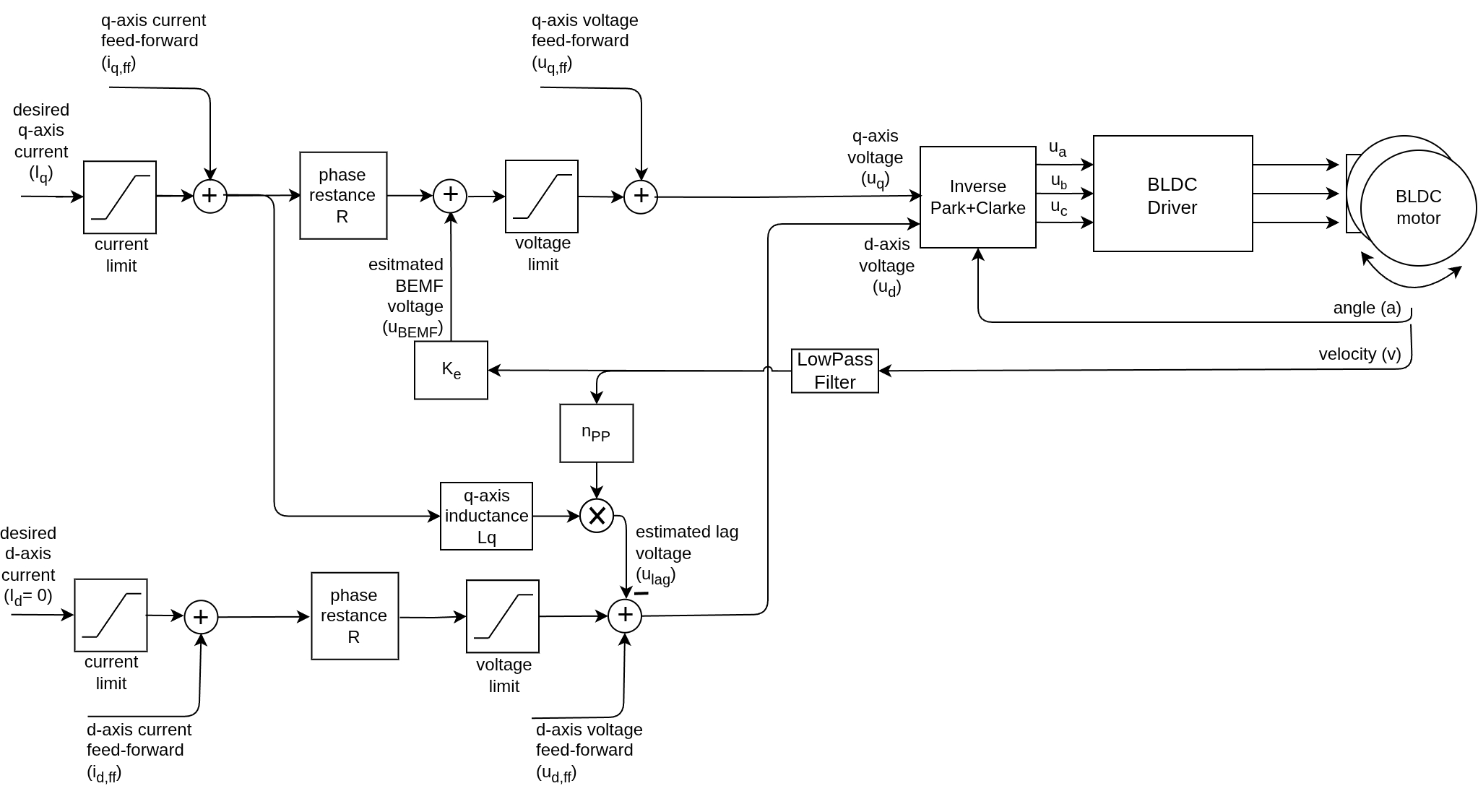

Estimated Current Mode

Type: TorqueControlType::estimated_current

BLDC motors Stepper motors Hybrid Stepper motors

Estimates the current based on motor parameters (phase resistance and KV rating) without requiring a current sensor. Provides better torque control than voltage mode but requires accurate motor parameters.

Implementation

From FOCMotor::loopFOC():

case TorqueControlType::estimated_current:

if(!_isset(phase_resistance)) return;

// constrain current setpoint

current_sp = _constrain(current_sp, -current_limit, current_limit) + feed_forward_current.q;

// calculate the back-emf voltage if KV_rating available

if (_isset(KV_rating)) voltage_bemf = estimateBEMF(shaft_velocity);

// filter the current estimate

current.q = LPF_current_q(current_sp);

// calculate the phase voltage: V = I*R + V_bemf

voltage.q = current.q * phase_resistance + voltage_bemf;

// constrain voltage

voltage.q = _constrain(voltage.q, -voltage_limit, voltage_limit) + feed_forward_voltage.q;

// d voltage - lag compensation

if(_isset(axis_inductance.q))

voltage.d = _constrain(-current_sp*shaft_velocity*pole_pairs*axis_inductance.q,

-voltage_limit, voltage_limit) + feed_forward_voltage.d;

else voltage.d = feed_forward_voltage.d;

break;

Motor Model

The voltage calculation is based on the motor electrical model:

\[u_q = R \cdot i_q + K_e \cdot \omega\]Where:

- \(u_q\) : Phase voltage

- \(i_q \cdot R\) : Resistive voltage drop

- \(K_e \cdot \omega = u_{BEMF}\) : Back-EMF voltage (calculated from velocity and KV rating)

Additionally the inductive voltage drop can be compensated if the motor inductance is known:

\[u_d = -L_q \cdot i_q \cdot \omega\]Configuration

motor.torque_controller = TorqueControlType::estimated_current;

motor.current_limit = 5.0; // Maximum current [A]

motor.voltage_limit = 12.0; // Maximum voltage [V]

// Required motor parameters

motor.phase_resistance = 2.5; // Phase resistance [Ohm]

motor.KV_rating = 100; // Motor KV rating [rpm/V] or provide via motor constructor

// Low pass filter velocity for BEMF compensation

motor.LPF_velocity.Tf = 0.01; // 10ms time constant

// Optional: lag compensation

motor.axis_inductance.q = 0.00015; // [H]

// Optional: feed-forward

motor.feed_forward_voltage.q = 0.0;

motor.feed_forward_voltage.d = 0.0;

Motor Parameter Identification

To use this mode effectively, you need to know your motor parameters. The library provides a helper function that uses current sensing to measure the motor’s phase resistance and inductance, which can then be used for better estimation even without current sensing in normal operation.

// In setup(), after motor.init() and motor.initFOC():

motor.characteriseMotor(voltage_test); // Measures R, L

See a deeper dive in estimated current control theory See the estimated current control API documentation Low-pass filter implementation

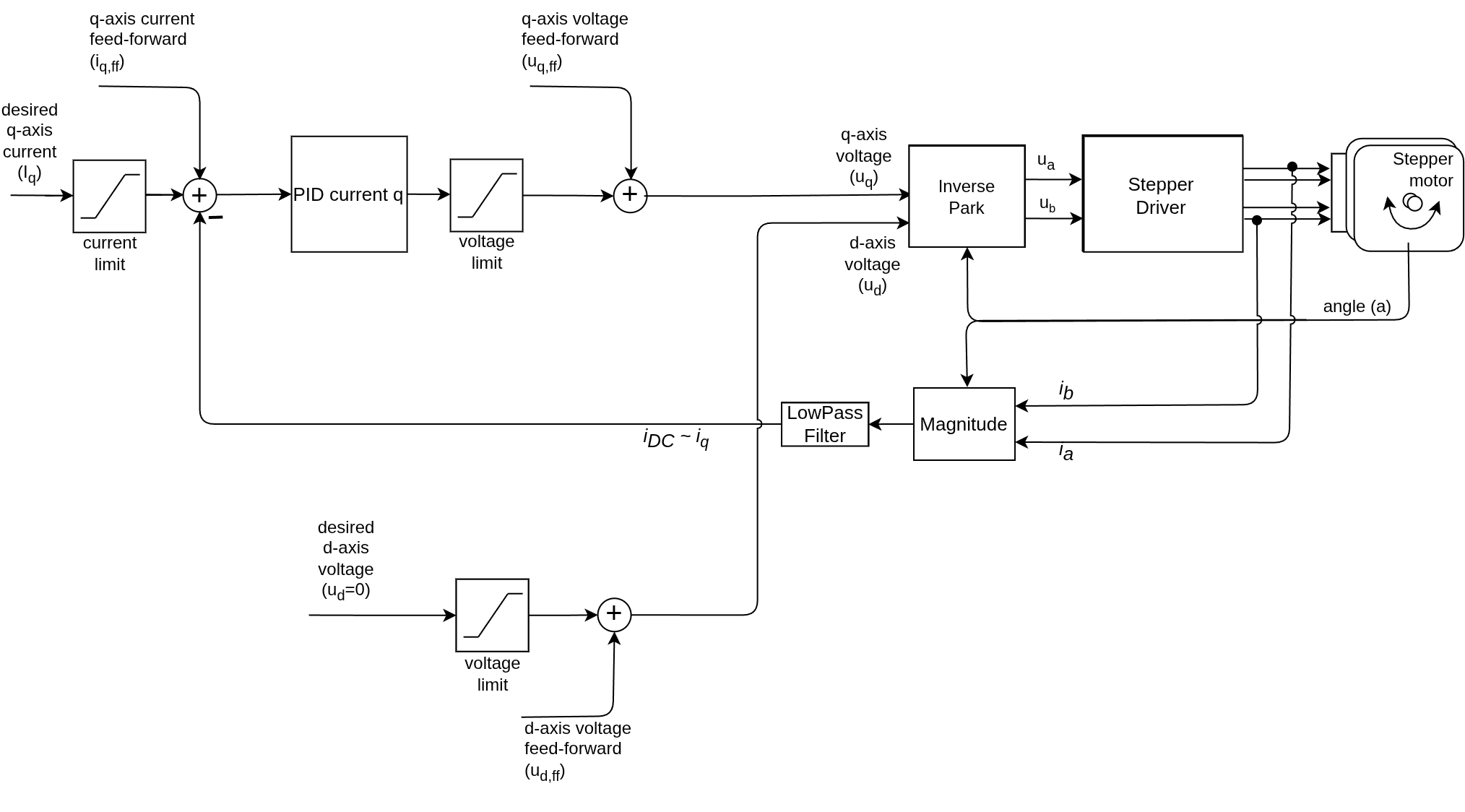

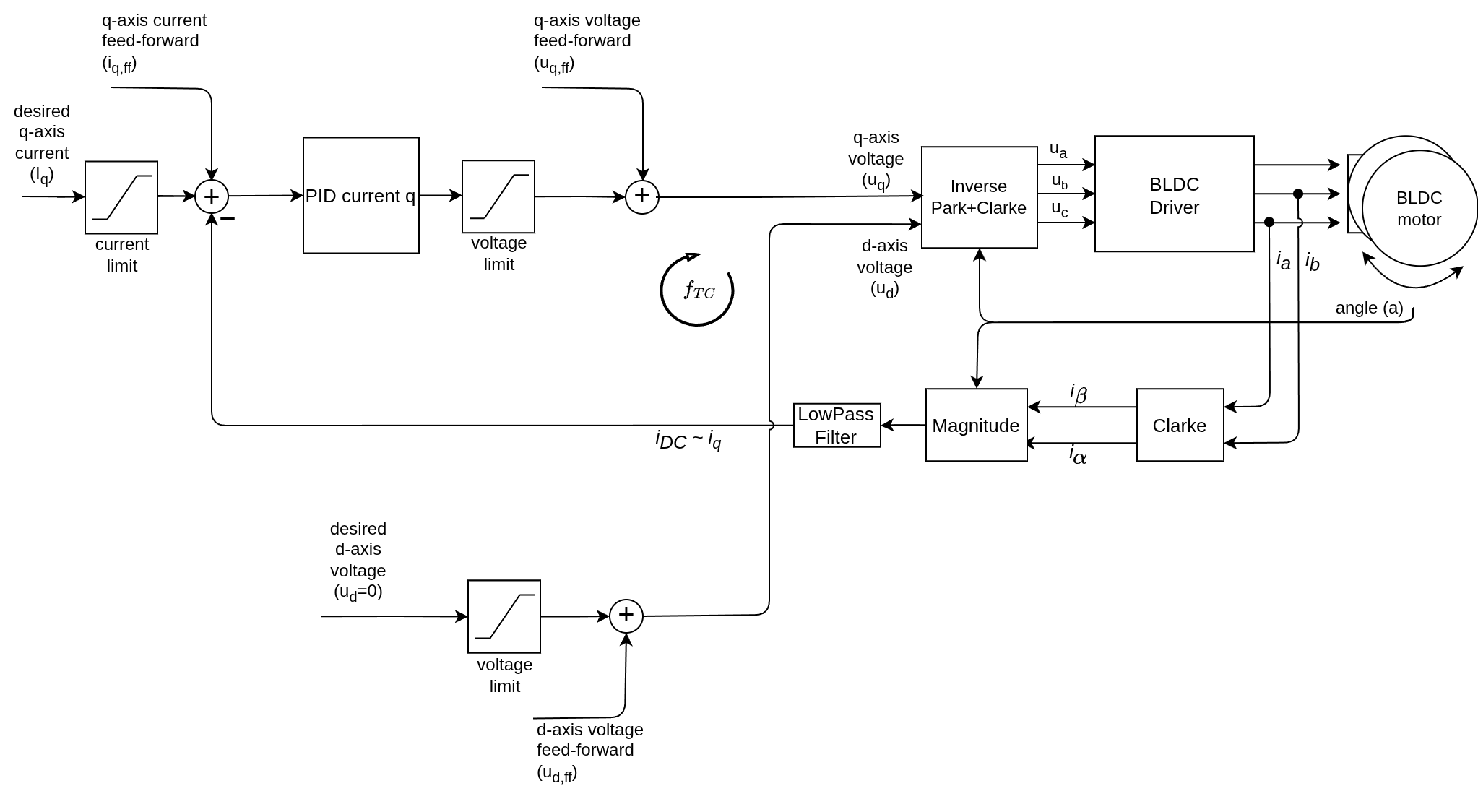

DC Current Mode

Type: TorqueControlType::dc_current

BLDC motors Stepper motors Hybrid Stepper motors

Uses current sensing to measure the overall current magnitude and regulates it with a PID controller. Requires a current sensor but only measures total current, not individual phase currents.

Implementation

From FOCMotor::loopFOC():

case TorqueControlType::dc_current:

if(!current_sense) return;

// constrain current setpoint

current_sp = _constrain(current_sp, -current_limit, current_limit) + feed_forward_current.q;

// read overall current magnitude

current.q = current_sense->getDCCurrent(electrical_angle);

// filter the value

current.q = LPF_current_q(current.q);

// calculate the phase voltage using PID

voltage.q = PID_current_q(current_sp - current.q) + feed_forward_voltage.q;

// d voltage - lag compensation

if(_isset(axis_inductance.q))

voltage.d = _constrain(-current_sp*shaft_velocity*pole_pairs*axis_inductance.q,

-voltage_limit, voltage_limit) + feed_forward_voltage.d;

else voltage.d = feed_forward_voltage.d;

break;

Configuration

motor.torque_controller = TorqueControlType::dc_current;

motor.current_limit = 5.0; // Maximum current [A]

motor.voltage_limit = 12.0;

// PID controller for current loop

motor.PID_current_q.P = 5.0;

motor.PID_current_q.I = 300.0;

motor.PID_current_q.D = 0.0;

motor.PID_current_q.output_ramp = 1e6;

motor.PID_current_q.limit = motor.voltage_limit;

// Low pass filter for current measurement

motor.LPF_current_q.Tf = 0.005; // 5ms time constant

// Optional: lag compensation (requires motor parameter)

motor.axis_inductance.q = 0.00015; // [H]

Advanced Features

Lag Compensation: Compensates for the phase lag introduced by motor inductance at high speeds, based on the motor model: \(u_d = -L_q \cdot \frac{di_q}{dt} \approx -L_q \cdot i_q \cdot \omega\)

Or in code:

voltage.d -= current_sp * shaft_velocity * pole_pairs * axis_inductance.q;

See the DC current control API documentation PID controller implementation Low-pass filter implementation

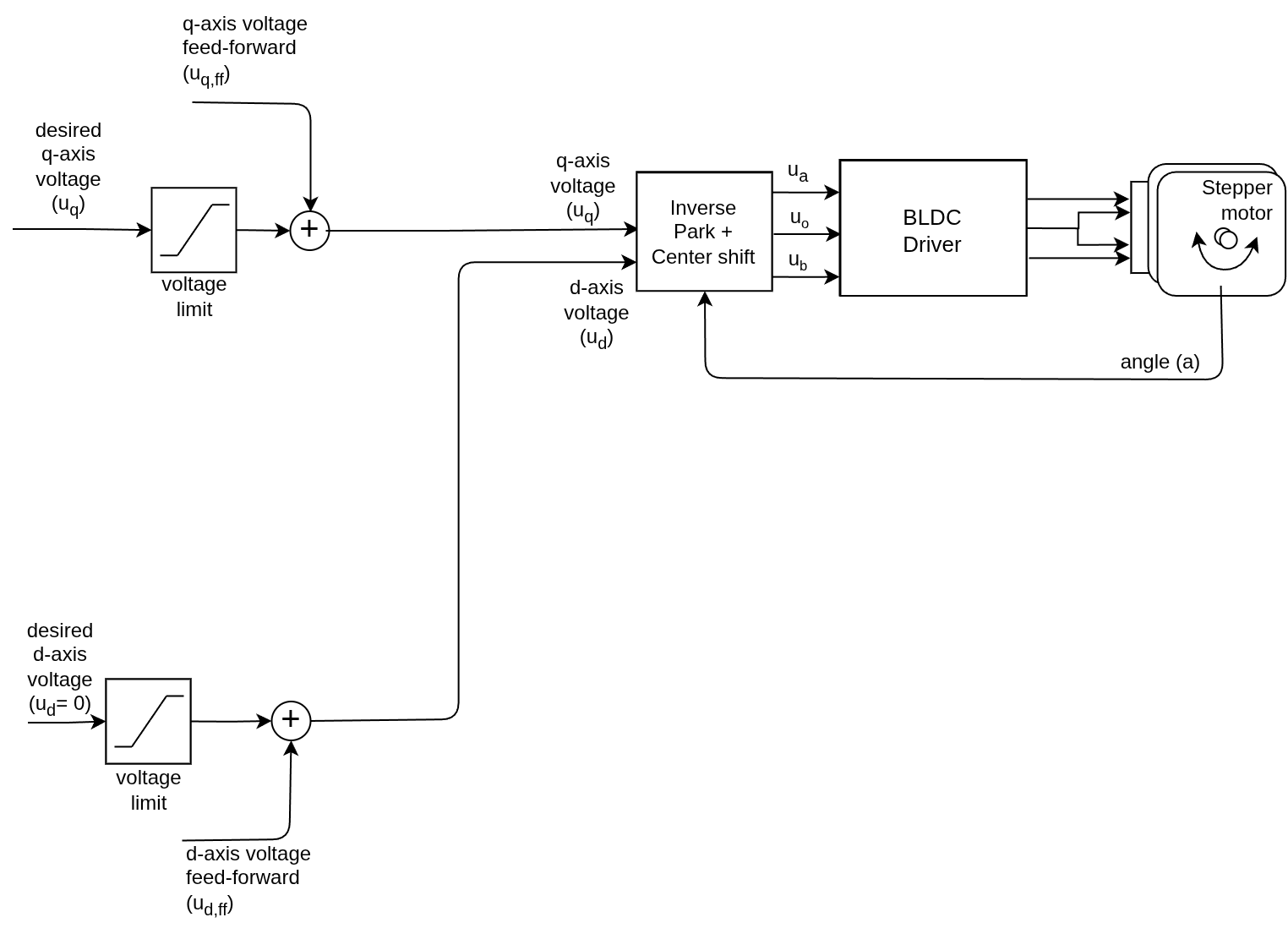

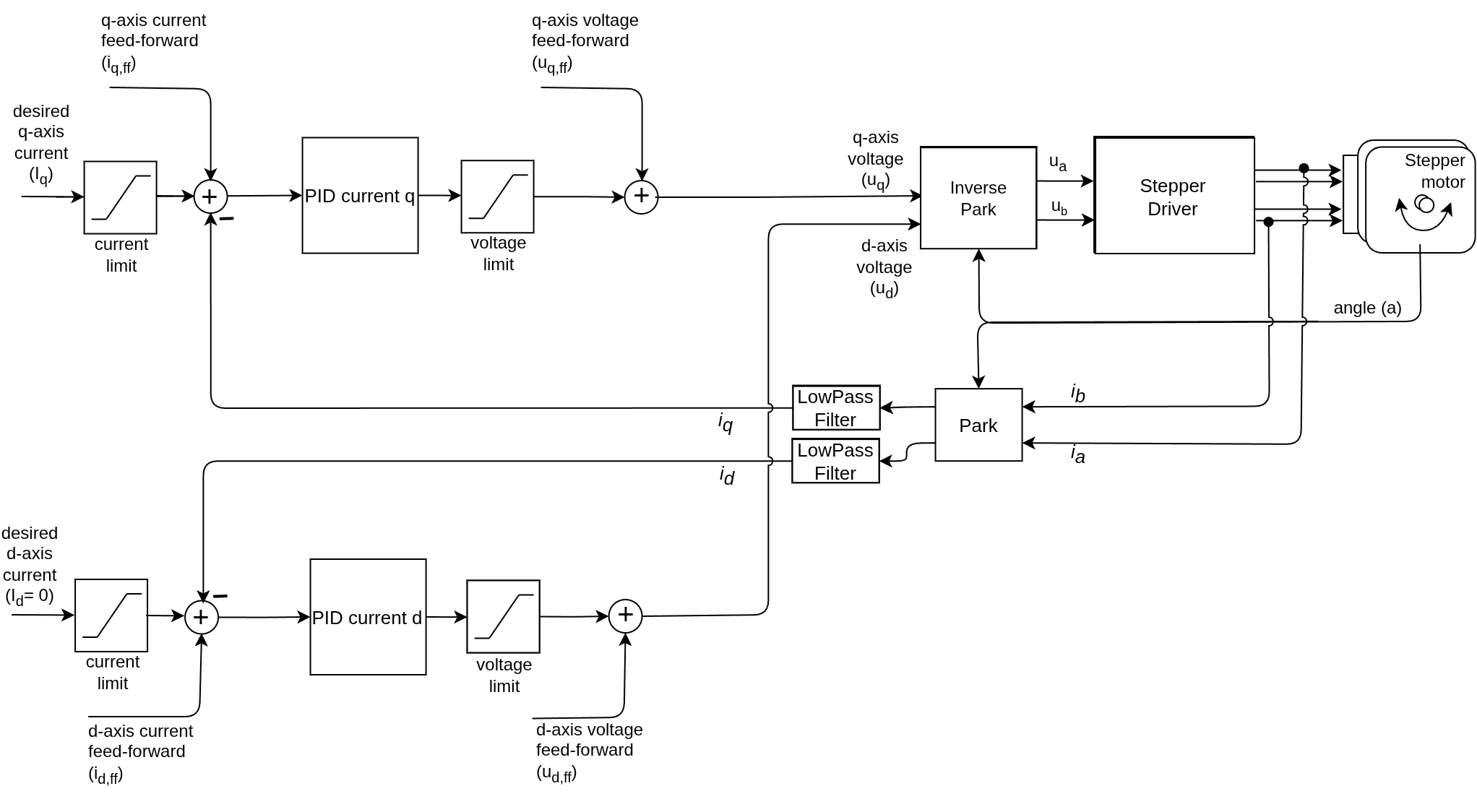

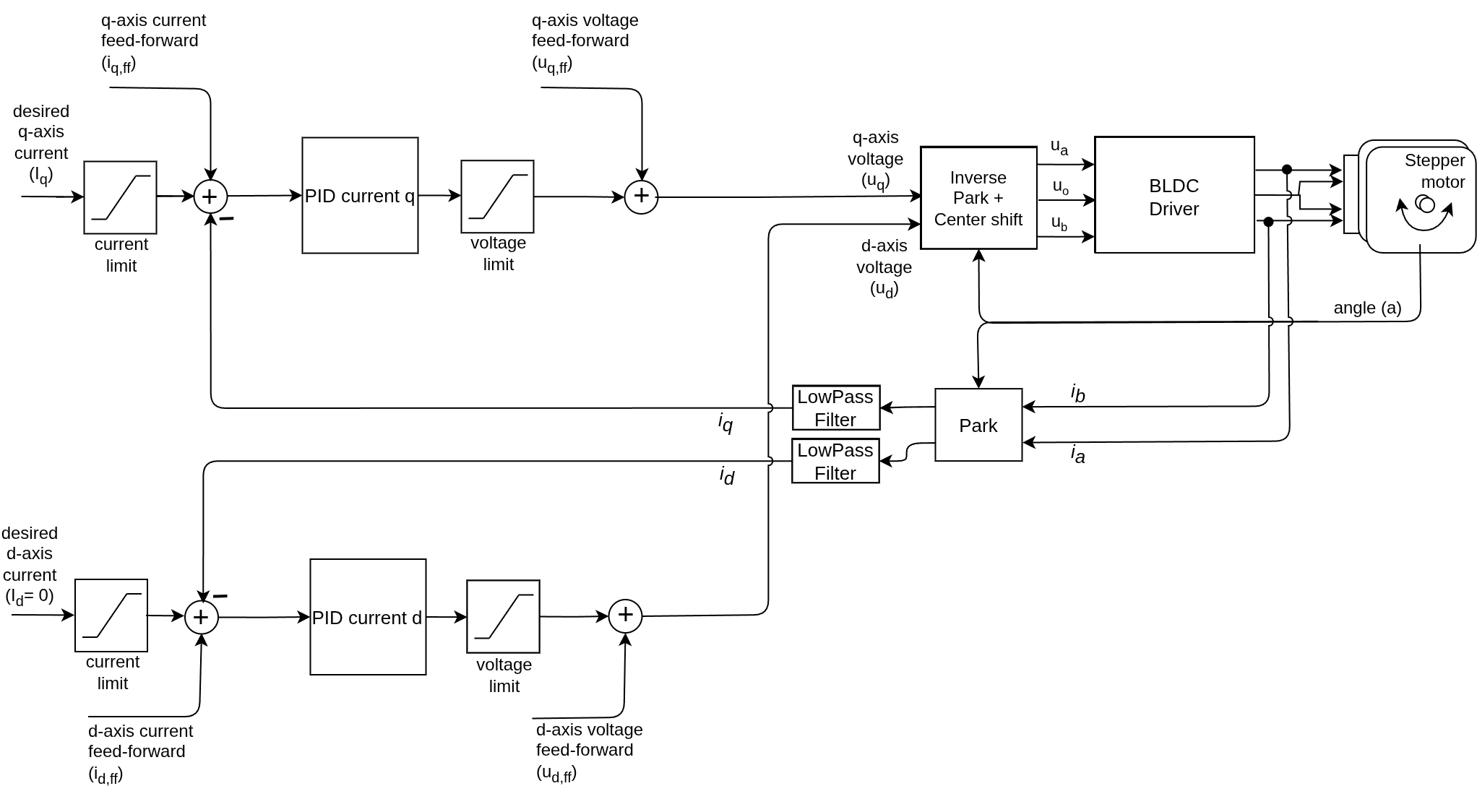

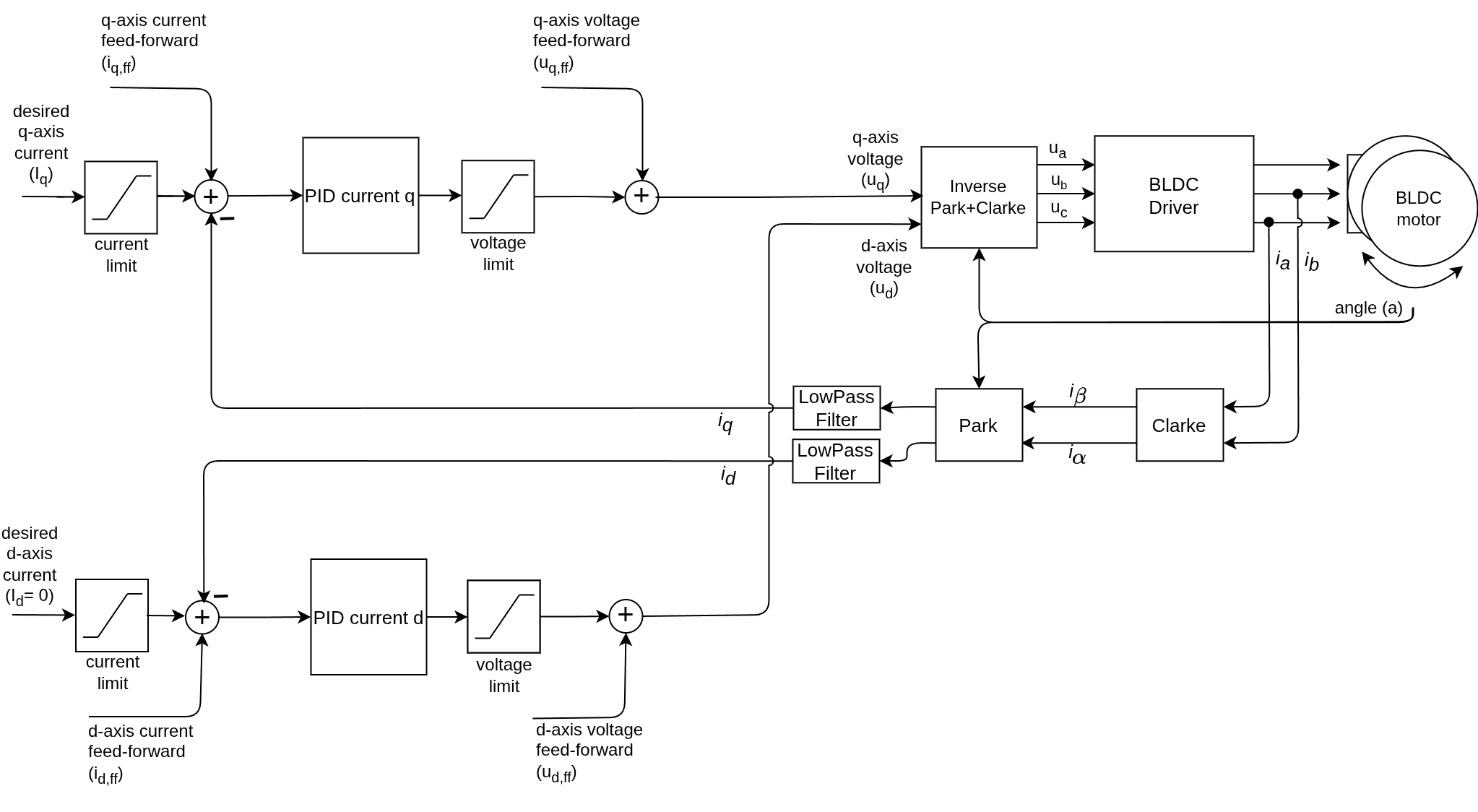

FOC Current Mode

Type: TorqueControlType::foc_current

BLDC motors Stepper motors Hybrid Stepper motors

The most accurate torque control method. Measures and controls both d and q axis currents independently using two PID controllers. This is true Field Oriented Control with full current feedback.

Implementation

From FOCMotor::loopFOC():

case TorqueControlType::foc_current:

if(!current_sense) return;

// constrain current setpoint

current_sp = _constrain(current_sp, -current_limit, current_limit) + feed_forward_current.q;

// read dq currents

current = current_sense->getFOCCurrents(electrical_angle);

// filter values

current.q = LPF_current_q(current.q);

current.d = LPF_current_d(current.d);

// calculate the phase voltages using two PIDs

voltage.q = PID_current_q(current_sp - current.q);

voltage.d = PID_current_d(feed_forward_current.d - current.d);

// lag compensation

if(_isset(axis_inductance.q))

voltage.d = _constrain(voltage.d - current_sp*shaft_velocity*pole_pairs*axis_inductance.q,

-voltage_limit, voltage_limit);

// cross coupling compensation

if(_isset(axis_inductance.d))

voltage.q = _constrain(voltage.q + current.d*shaft_velocity*pole_pairs*axis_inductance.d,

-voltage_limit, voltage_limit);

// add feed forward

voltage.q += feed_forward_voltage.q;

voltage.d += feed_forward_voltage.d;

break;

Configuration

motor.torque_controller = TorqueControlType::foc_current;

motor.current_limit = 5.0; // Maximum current [A]

motor.voltage_limit = 12.0;

// Q-axis PID controller (torque-producing current)

motor.PID_current_q.P = 5.0;

motor.PID_current_q.I = 300.0;

motor.PID_current_q.D = 0.0;

motor.PID_current_q.output_ramp = 1e6;

motor.PID_current_q.limit = motor.voltage_limit;

// D-axis PID controller (flux-producing current)

motor.PID_current_d.P = 5.0;

motor.PID_current_d.I = 300.0;

motor.PID_current_d.D = 0.0;

motor.PID_current_d.output_ramp = 1e6;

motor.PID_current_d.limit = motor.voltage_limit;

// Low pass filters

motor.LPF_current_q.Tf = 0.005; // 5ms

motor.LPF_current_d.Tf = 0.005; // 5ms

// Optional: motor inductances for compensation

motor.axis_inductance.q = 0.00015; // [H]

motor.axis_inductance.d = 0.00015; // [H]

// Optional: feed-forward

motor.feed_forward_current.d = 0.0; // Usually 0 for surface-mount motors

motor.feed_forward_voltage.q = 0.0;

motor.feed_forward_voltage.d = 0.0;

PID controller implementation Low-pass filter implementation

Advanced Features

Lag Compensation:

Based on the motor electrical model, the inductive voltage drop can be compensated to improve high-speed performance:

\[u_d = -L_q \cdot \frac{di_q}{dt} \approx -L_q \cdot i_q \cdot \omega\]Compensates for the phase lag introduced by motor inductance at high speeds:

voltage.d -= current_sp * shaft_velocity * pole_pairs * axis_inductance.q;

Cross-Coupling Compensation:

Based on the motor model, the interaction between d and q axes can be compensated to improve accuracy:

\[u_q = R \cdot i_q + K_e \cdot \omega + L_d\frac{di_d}{dt} \approx R \cdot i_q + K_e \cdot \omega + L_d \cdot i_d \cdot \omega\]Compensates for the interaction between d and q axes:

voltage.q += current.d * shaft_velocity * pole_pairs * axis_inductance.d;

See the FOC algorithm theory documentation

Quick Selection Guide

Choose Voltage Mode if:

- No current sensing available

- Low-power applications (gimbal motors)

- Cost is primary concern

- Basic control is sufficient

Choose DC Current Mode if:

- Single shunt or DC link sensing available

- Need current limiting

- Cost-sensitive but need better accuracy than voltage

Choose FOC Current Mode if:

- Highest performance required

- Current sensing hardware available

- Applications requiring precise torque control

- High-speed operation with field weakening

Choose Estimated Current Mode if:

- No current sensing available

- Motor parameters are well known

- Need current limiting without hardware

- Better accuracy than voltage mode required

See more info in the torque control API documentation

Implementation in loopFOC()

All torque control modes are executed in the loopFOC() function. Here’s the overall flow:

void FOCMotor::loopFOC() {

// Update sensor

if (sensor) sensor->update();

// If disabled or not ready, return

if(!enabled || motor_status != FOCMotorStatus::motor_ready) return;

// Calculate electrical angle

electrical_angle = electricalAngle();

// Execute torque control based on selected mode

switch (torque_controller) {

case TorqueControlType::voltage:

// Direct voltage control

break;

case TorqueControlType::dc_current:

// DC current control with PID

break;

case TorqueControlType::foc_current:

// Full FOC with d/q current control

break;

case TorqueControlType::estimated_current:

// Model-based current estimation

break;

}

// Apply calculated voltages to motor phases

setPhaseVoltage(voltage.q, voltage.d, electrical_angle);

}

The setPhaseVoltage() function then uses the FOC algorithm to convert d/q voltages into three-phase voltages (or two-phase for stepper motors) and applies them via PWM.

See the FOC algorithm implementation docs

Related Documentation

Motion Control Implementation PID Implementation Low-Pass Filter Implementation